Sparxell, the Cambridge-based pioneer of plant-based colourant technology, has secured a €1.9 million grant from the European Innovation Council (EIC), positioning the company to overcome critical technical barriers in scaling its world-first natural colourants.

This prestigious funding recognises Sparxell's breakthrough technology as part of the Council's mission to identify, develop and scale up disruptive innovations that address global challenges.

Benjamin Droguet with Sustainable Materials taken by Gabriella Bocchetti.©University of Cambridge.

Sparxell was founded by Ben during his time with the Vignolini Group using cellulose to make stunning pigments with natural structural colour (as opposed to dyes). Structural colour arises from how light interacts with a molecular structure so the colours do not fade like dyes do.

Sparxell’s pigments are made from cellulose and are biodegradable. They deliver stunning colours that outperform synthetic alternatives without fossil-based chemicals, instead taking inspiration from nature to create colour.

Since spinning out of the University of Cambridge in 2023, Sparxell has gained rapid commercial validation through over 25 fully funded pilot projects with global brands across diverse industrial sectors. The company has earned multiple industry accolades, including the Biomimicry Institute's \$100k Ray of Hope Award, \$250k from Morgan Stanley's Sustainable Collaborative Prize, and being named "Best Sustainability Venture" by the Falling Walls Foundation.

Red glitter made from cellulose from Sparxell.

With the company approaching its first million in sales, the EIC grant will prime Sparxell for growth in the colourants sector. The company is scaling to tonne-level production in 2025, in preparation for its first commercial launch with leading brands and manufacturers.

Ben said: "This European Innovation Council funding is transformative for Sparxell, allowing us to accelerate our manufacturing scale-up and overcome key technical challenges much earlier in our development pathway.

"With our plant-based technology, we're offering industries a fundamentally different approach to colour that works with nature rather than against it while meeting the highest performance standards."

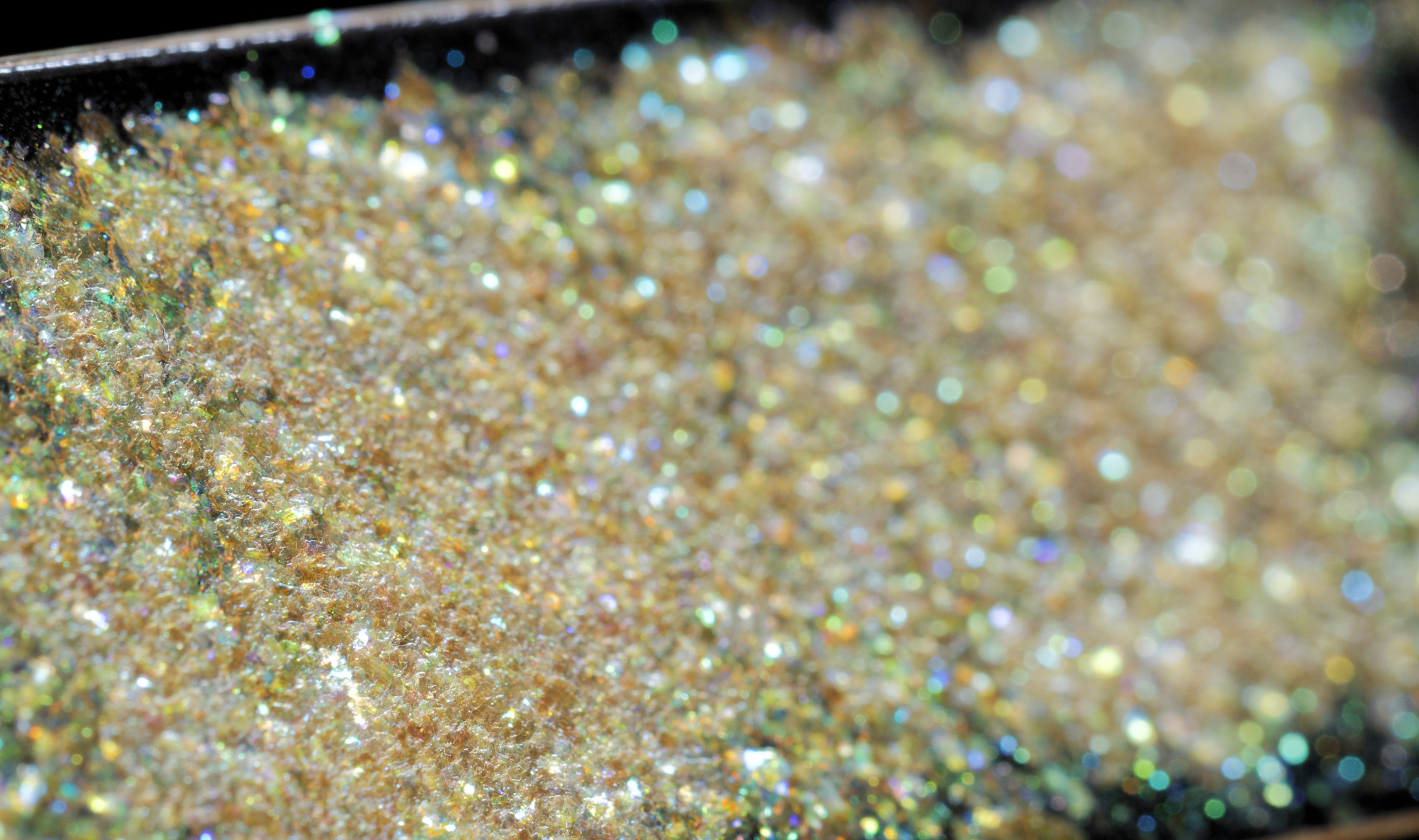

Gold glitter made from cellulose.

Sparxell’s proprietary technology uses cellulose from readily available materials, including wood pulp and agricultural waste. The resulting colours exceed the performance of synthetic dyes in both colour intensity and durability and are completely non-toxic and biodegradable.

In fashion, the technology significantly reduces energy and water consumption compared to conventional textile dyeing and printing. It also eliminates toxicity in human-contact applications such as cosmetics and food applications, while enabling large-scale recycling and circularity across industries, such as packaging and paint.

Last autumn, Sparxell expanded its Cambridge headquarters capacity, enabling kilogram-scale production to accelerate innovation and meet increasing market demand.