This methodology can be used to compare any electrolytes in not just zinc batteries but also sodium, lithium, and others.

A zinc metal battery is made of two electrodes and a separator which are submerged in a salt solution called an electrolyte. This work, which was published 14 August 2024 in the Journal of Materials Chemistry A, tested their methodology on different concentrations of electrolyte and discovered that a dilute concentration was more efficient. The battery with a less concentrated solution performed better and more consistently over many cycles of charging and discharging. Their results showed that by using a smoother, more consistent interface improved the zinc battery’s performance.

James Simon, second year PhD student in the Menkin group who led this research, commented: “Aqueous electrolytes are low-cost, safer and more abundant which are huge advantages when developing zinc batteries.”

Dr Svetlana Menkin, who leads the group, commented: “Battery safety and longevity are critical for electrification and renewable energy storage. Our research works to realise a more sustainable generation of batteries.”

Battery safety and sustainability

Lithium batteries are typically the type you would find in your phone and they are preferred for this technology because they are small and portable.

Zinc batteries are more sustainable than alternatives like lithium and because they use water based electrolytes instead of organic solvents. The salts used in zinc batteries are non-fluorinated with fewer additives and have a lower environmental demand.

Zinc batteries are safer than lithium or sodium batteries because they do not catch fire in the unlikely event of catastrophic failure. More importantly, producing zinc batteries is safer and does not require an energy-intensive process or high-cost production facilities. Moreover, zinc batteries are easier to recycle.

James adds: “Zinc has a few benefits over lithium batteries. Because the electrolyte in a zinc battery is water-based it is less likely to catch fire, whereas lithium batteries can catch fire if they are pierced or get too hot.”

Zinc needles and reliability

The study tested two concentrations of the electrolyte in a zinc battery about the size of a pound coin.

The water-based electrolyte transfers charge between two plates inside the battery. When the battery is charging, a layer of zinc builds up on one electrode and it degrades when the battery is in use.

Scanning electron microscopy visualisation of zinc needles forming on the surface of the battery with concentrated electrolyte after five cycles of charge and discharge. Courtesy the Menkin group.

One problem the team are addressing is how to encourage the layer of zinc to grow evenly. Zinc can grow in needle shapes and, if the needle touches the opposite electrode, this shorts the battery, and it drastically decreases in efficiency and leads to battery failure.

In the experiment, the battery with dilute electrolyte worked consistently with good surface conductivity for many cycles. Whereas the battery with concentrated electrolyte soft shorted by the tenth cycle and had reduced performance. This is because the concentrated electrolyte caused hotspots on the interface and grew zinc needles. This shorted the battery and shortened the battery life.

Scanning electron microscopy visualisation of the zinc forming on the surface of the battery with dilute electrolyte after five cycles of charge and discharge. Courtesy the Menkin group.

In situ measurements

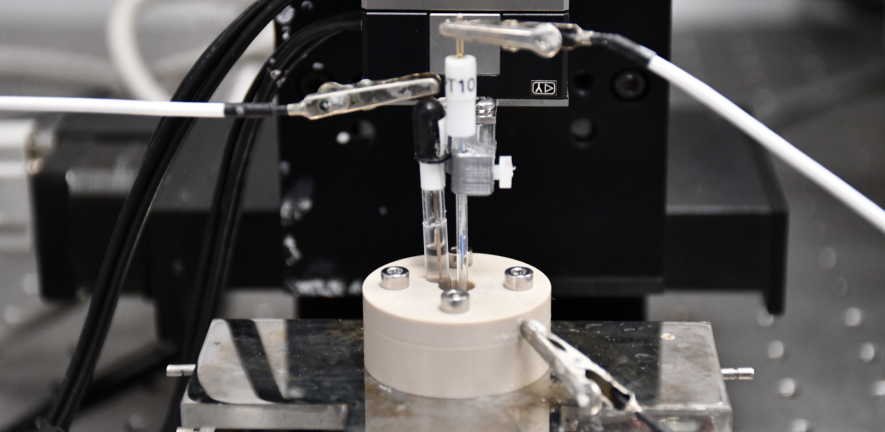

The team used scanning electrochemical microscopy, a microscope that monitors electrochemical changes to visualise how the interfaces changed inside the battery as it charged and discharged. If the interface is homogeneous electrochemically then the battery has a longer cycle-life.

They also used X-Ray photoelectron spectroscopy and Raman spectroscopy to determine the composition of the electrodes’ interfaces and measure their conductivity. These experiments were performed by Dr Veronika Šedajová, Dr Debashis Tripathy and Holly Smith who are all part of the Yusuf Hamied Department of Chemistry.

Research

J. T. Simon, V. Šedajová, D. Tripathy, H. E. Smith, S. M. Clarke, C. P. Grey and S. Menkin, The effect of interface heterogeneity on zinc metal anode cyclability, Journal of Materials Chemistry A (2024).

This work was funded thanks to the Faraday Institute SafeBatt and the Royal Society University Research Fellowship.