Our new resource recovery system aims to remove the concept of ‘waste’ from the university, according to Facilities Management Operations Manager Steve Matthews, who has led the planning and implementation of the scheme with the University sustainability team.

The new bins and signage around the department are for food waste and resource reclaiming, and are part of the University's goal to make the University more sustainable. Even the bins are made from 100% post-consumer plastic.

“Something we would see with the previous system is that people were unsure about which bin to use for their waste, so they would default to the general waste bin which goes to landfill,” explains Steve. “So our new approach is to try to remove the decision-making process. All recyclables, glass, tin, paper, etc, go into one bin, and a computer-controlled Mechanical Recovery Plant sorts it out into the different resource streams."

How it works

We now have two types of bins: resource recovery and food waste.

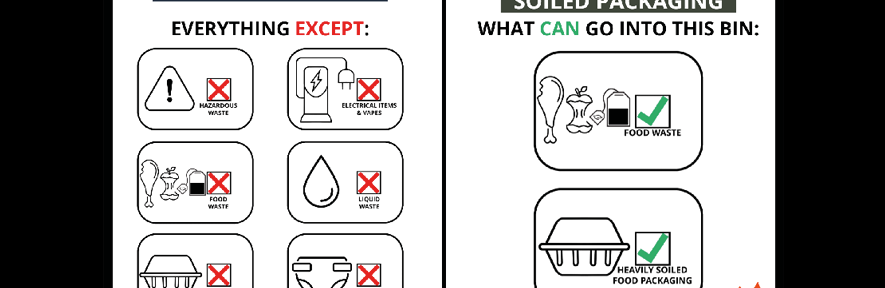

You can dispose of paper, glass, foil, tin cans, plastic, cardboard, clingfilm, polystyrene and even plastic bags into the bins labelled resource recovery.

The food waste bins are for food and soiled packaging, including egg shells and bones, as well as soiled packaging. Steve says this waste will go to an Anaerobic Digestion Plant, where it will produce biogas, with the residue going into the energy-from-waste stream.

The laboratories only have resource recovery bins and not food waste bins. Laboratory glass, sharps, and chemical waste are disposed of separately using the current procedures.

One frequently asked question is what to do with coffee cups: The answer is that disposable cardboard which has liquids inside that are still visible, e.g. coffee foam, should go into the food bin. But if the plate, cup or container is lightly soiled it can go into the resource recovery bin. Steve says that if you are in doubt whether a container has heavy food contamination, it should go into the food waste bin.

In general, if a carton will dry within 24 hours then it's okay to put it in the black bin. If an item isn’t recyclable then the firm will remove it at the depot and it will go towards reclaimed fuel. Even the burnt waste ash is used in cement.

Recycling journey

Food and food-soiled packaging is collected by Mountain Recycling and sent to a processing plant that can recover 300 kWh of energy per one tonne of food waste, which is the equivalent to leaving a lightbulb on for a fortnight.

The process uses an anaerobic digestion facility and turns into biogas and fertiliser. The small amount of materials which cannot be recycled will be recovered and make their way to cement factories in the UK to be used as coal replacement fuels.

The dry waste goes to Haverhill and then Barkston for sorting, where they can reclaim around 80% of the waste they receive as a minimum. "We are looking to increase this as the system progresses," says Steve.

The waste makes a journey through several sheds, which use over 22 miles of conveyor belts and AI-assisted technology, including infrared, 2D and 3D detectors, magnets and tumblers. Along the way items are sorted into categories like paper, plastic, glass and tetra packs. The sorting is very discerning and can even separate newspaper from printer paper.

Steve is organising visits open to staff later in the year to see the operation in person. He says to keep an eye out for the email.

Suggestions

“We’ve had a lot of questions,” says Steve, which he is happy about because it means people are aware of the new system and want to do the right thing. “If people aren’t sure then please ask!” he says, emphasising that his inbox is always open for questions and suggestions. This also means the sustainability team can continue to improve the system before term starts in October.

“Our hope is that by the time we get to term we will have a fully integrated resource recovery system up and running smoothly, which we can introduce to our new students."