The most spectacular colours in the natural world arise from photonic structures, such as the helicoidal arrangement of cellulose in the fruit of Pollia condensata. These natural examples inspire us to investigate how biological building blocks such as cellulose and chitin can be used to create more sustainable colorants.

Cellulose is a sugar-based polymer found in virtually all plants, making it one of the most abundant natural materials in the world. Cellulose can be extracted from natural sources in the form of thin rigid rods known as cellulose nanocrystals (CNCs). Individual CNCs are less than a micron long - too small to be seen by the human eye, even under an optical microscope - but if CNCs are brought together at high enough concentrations, their collective behaviour can produce photonic structures that exhibit dazzling colour. This spontaneous formation of a highly ordered structure from simple components is known as self-assembly.

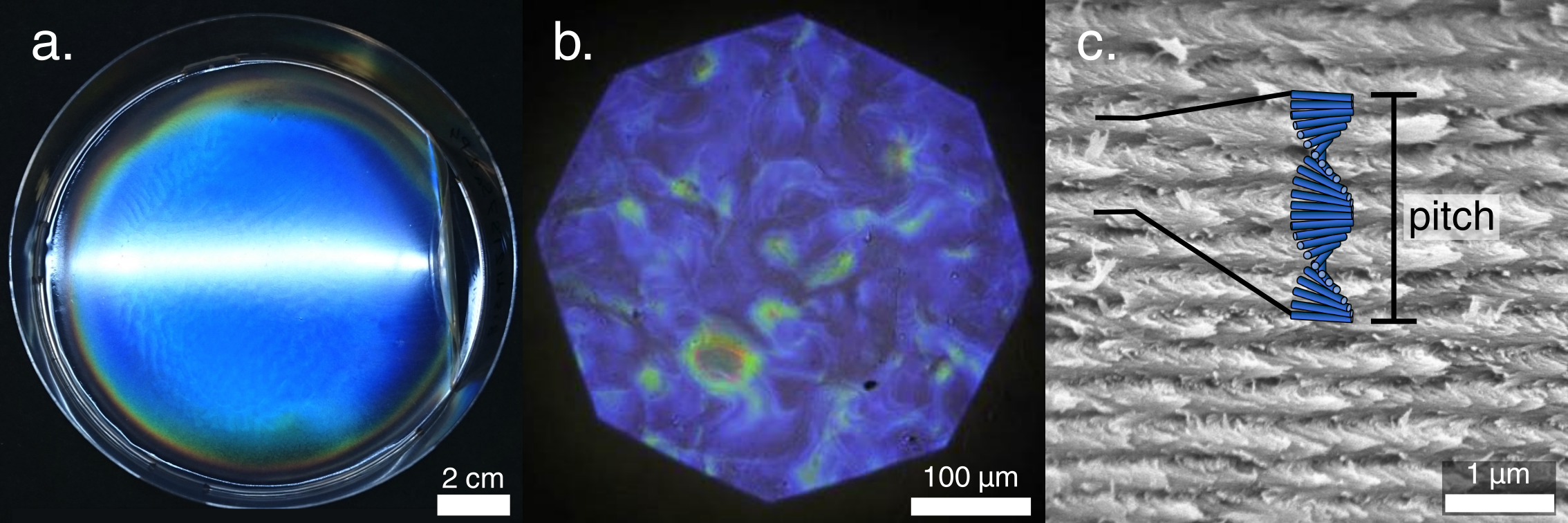

a) A photograph of a dried CNC film, showing blue structural colour

b) A blue CNC film as seen under an optical microscope using reflected light (epi-illumination)

c) SEM image of a cross-section of a CNC film, revealing the periodic helicoidal structure created by the self-assembly process, with the cholesteric pitch indicated.

To initiate the self-assembly process, the cellulose nanocrystals are first suspended in water at a low concentration and left to dry. As the water evaporates, the CNC concentration increases. At high enough concentration, the rod-shaped CNCs begin to assemble together to form a configuration known as a cholesteric lyotropic liquid crystal phase. If the water is allowed to evaporate entirely, a solid film of cellulose is produced, preserving the twisted cholesteric structure.

The intense colour of the CNC films arises from the helicoidal structure created by self-assembly. The twisting configuration of the CNCs forms a pattern that repeats over a certain distance, known as the pitch. This periodic structure reflects light at a certain wavelength (i.e. at a certain part of the spectrum) corresponding to the pitch. If we change the pitch, the colour of the film changes accordingly: a film with a larger pitch reflects longer-wavelength light, so the colour is red-shifted, while a film with a smaller pitch reflects shorter-wavelength light, causing a blue-shift.

By changing the conditions of the CNC self-assembly process, we can change the colour of the films, and more generally control their visual appearance. For example, adding salt to the suspension at the start of the self-assembly process causes the pitch to be smaller, causing a blue-shift in the colour.

We are investigating the effect of many different factors on CNC self-assembly in a variety of geometries, from large-scale films to printed microfilm arrays and pigment powders.

The structural colour of CNC films creates a unique connection between their macroscopic visual appearance and their microscopic structure. For example, the dried CNC film appears different colours from different angles. We can measure this colour change using a spectrometer. We have recently discovered that the way the colour changes with angle shows us how exactly the film dried, which is useful in helping us understand how the self-assembly process works.