Hydroxypropyl cellulose (HPC) is a derivative of cellulose that gives rise to bright colours when in its liquid crystalline phase and is responsive to external stimuli. It has the advantages of being biocompatible and edible and as such, commonly found as a thickening agent in pharmaceuticals and in food products (for example, it is used as a thickener in sauces and dips, or as a stabiliser in whipped cream).

Cellulose is what constitutes paper, how do we go from colourless to colour?

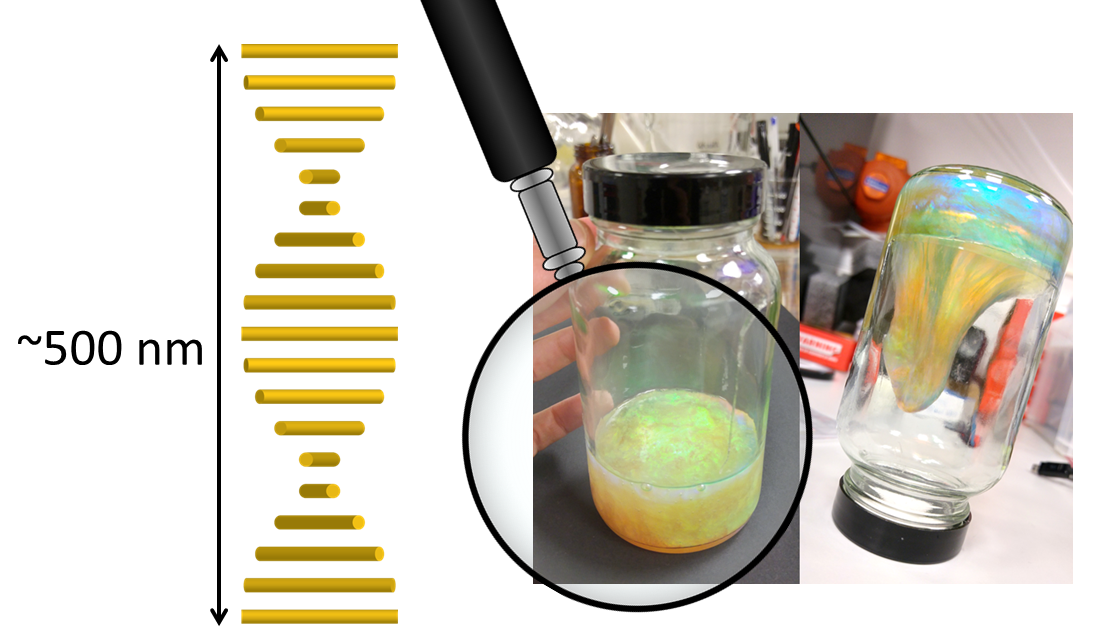

The phenomenon that makes HPC coloured is called structural colouration. A glass of soap and water is colourless but when blown into bubbles, the shell of the bubbles has the same dimensions that wavelength of visible light. This transparent layer interacts with light and by a process of constructive and destructive light interferences, we see rainbow-like colours. The structure that is responsible for the colours of HPC is called a cholesteric structure. The polymer chains self-assemble into a twisted stack and reflect light selectively for a narrow region of wavelengths that match the dimension of the structure’s periodicity.

What would be a possible application for this material?

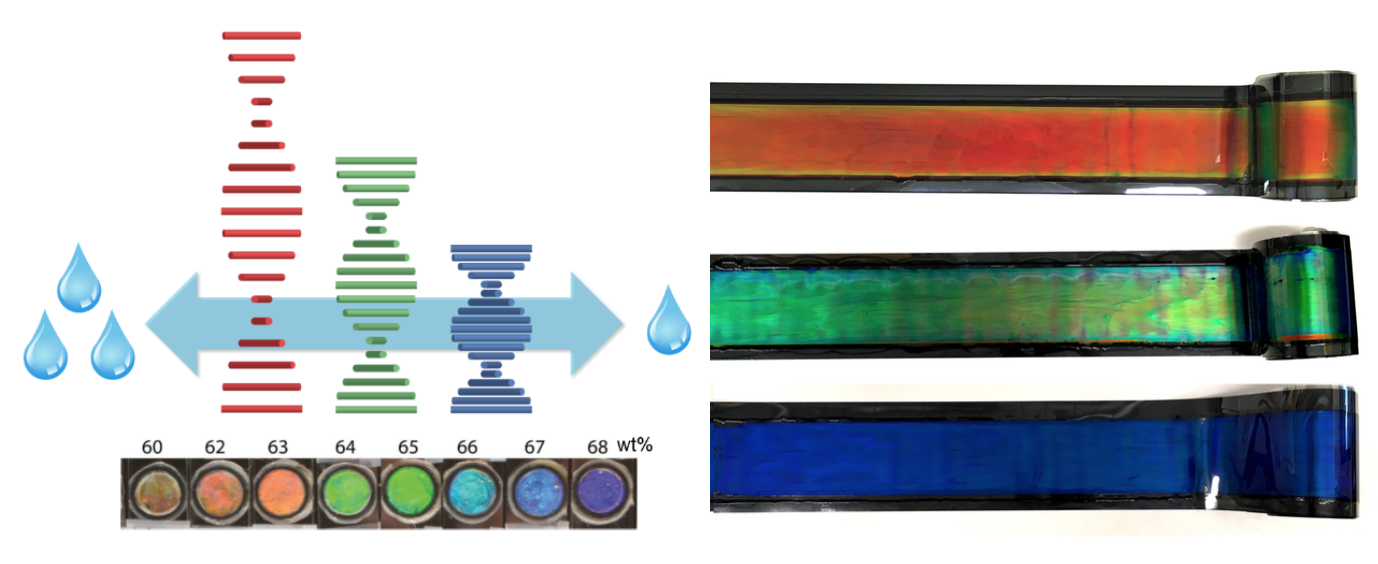

The cholesteric structure of HPC is formed by self-assembly. HPC is a polymer liquid crystal that spontaneously forms helicoids when mixed with water under the right proportions. This makes it an easy to fabricate, liquid (therefore processable) coloured material, whose colour can be tuned simply by changing the water content. In addition, HPC is responsive to pressure and temperature. In this lab, we have studied how the helicoidal structures respond to vertical compression and we have fabricated a large-scale pressure sensor using a roll-to-roll machine to map foot pressure in a way that is directly understandable by the human eye.

What are the current challenges we are working on?

A large range of colour can be obtained by varying the concentration of HPC, but that can pose a problem for further development as the colour of dry HPC lies in the UV. In this lab, we focus on understanding the self-assembly of HPC through optical measurements as well as designing approaches towards a visibly coloured sold-state HPC material.