Biography:

2023: Joined the BIP group's spin off company "Sparxell" as Head of R&D to commercialise the cellulose based photonic materials.

2020-2023: Worked as a technical consultant at The Technology Partnership (TTP) near Cambridge, focusing on microfabrication, microfluidics and software development

2016: PhD in Chemistry, University of Cambridge, UK

2015: MPhil in Materials Science, University of Cambridge, UK

2012: Bachelor in Materials Science, Monash University, Australia

2010: Bachelor in Materials Science and Engineering, Central South University, China

Research Interests:

Structural colours refer to the colours that arise from coherent interference of light when interacting with the nanostructures. There are countless examples of structural colors in nature, such as butterfly wings, beetles exoskeleton and polia fruits. In our group, we mainly focusing on reproducing the effect using natural biopolymers, such as cellulose and its derivatives. We aim to create photonic pigments that are long-lasting, responsive, low-cost and safe for applications in food colourings, cosmetics and bio-sensors.

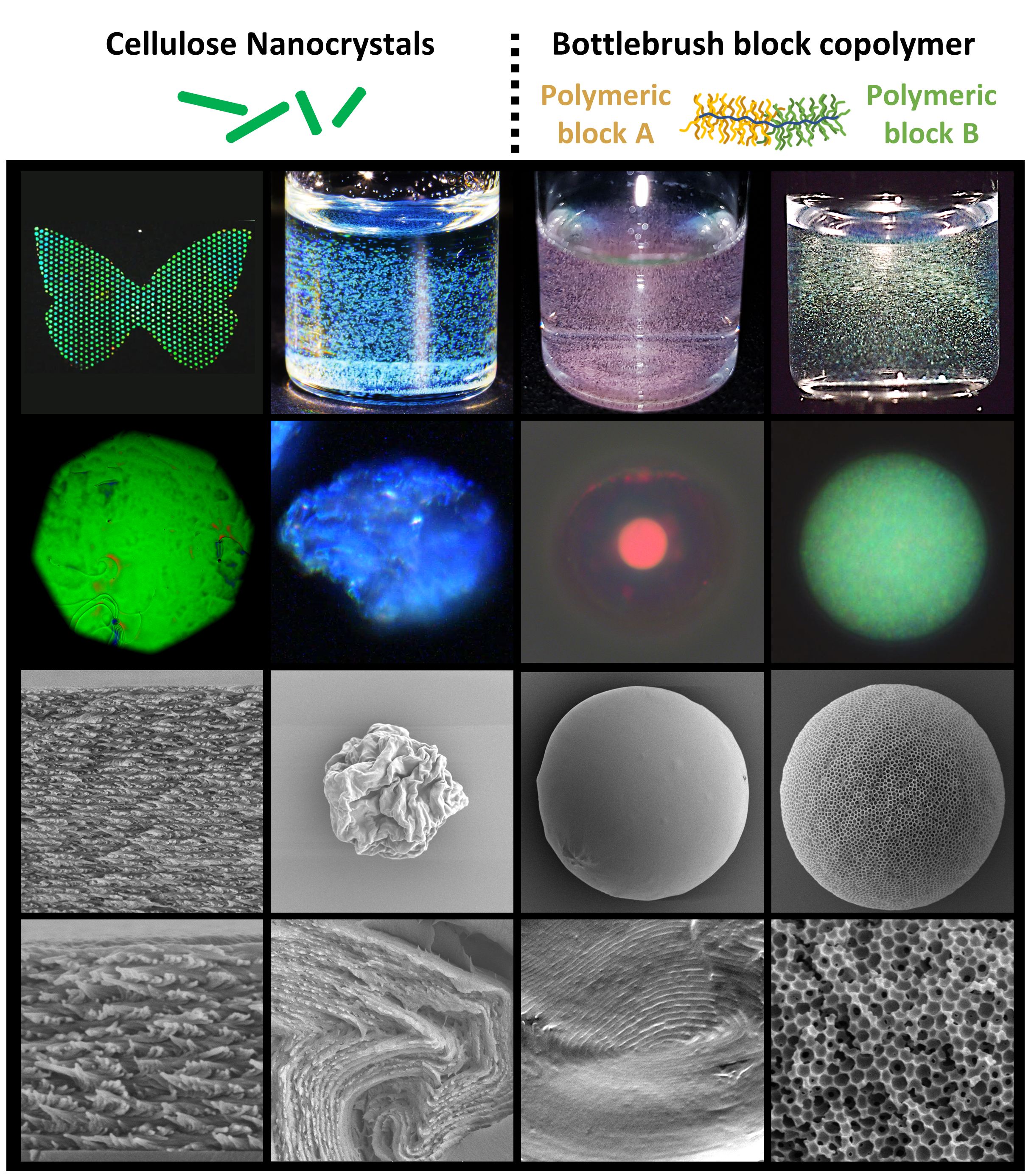

Personally, my research emphasises the importance of geometrical confinement on the result of self-assembly of the photonic materials building block. The first building block is Cellulose Nanocrystals (CNCs), which is obtained from acid hydrolysis of cellulose, often from filter paper or cotton. The CNCs have a special capability to arrange into a liquid crystalline structure, cholesteric phase, which has an inherent period that is close to visible light wavelength when dried. By confining the CNCs suspension into miniscure sessile droplets or spherical droplets, the quality of the self-assembly immediately got improved and new properties like humidity sensitivity was obtained. I have also been collaborating with other research groups to apply the same trick with synthesised polymers, such as bottlebrush block co-polymers (BBCPs). Again, the confinement has been shown to greatly improve the self-assembly quality and gives us unexpected results.

Figure: Highlights of all my works in one figure. From left to right: the printed CNC microfilms, CNC microparticles, PS-PDMS bottlebrush block copolymer microspheres, and porous PS-PEO bottlebrush block copolymer microspheres. From top to bottom: macroscopic photos, microscopic optical images, SEM of zoomed out and SEM of zoomed-in images.